Wood drying

The moisture content of wood need to be controlled in a certain level to prevent them from shrinkage, cracking, swelling and deformation problems. For example, it is about 10%-12% in the south, 8%-10% in the north and 6%-8% in the northwest of China.Only by that way can effectively improve the processing and use performance and durability of wood and its finished products!

The moisture content of wood need to be controlled in a certain level to prevent them from shrinkage, cracking, swelling and deformation problems. For example, it is about 10%-12% in the south, 8%-10% in the north and 6%-8% in the northwest of China.Only by that way can effectively improve the processing and use performance and durability of wood and its finished products!

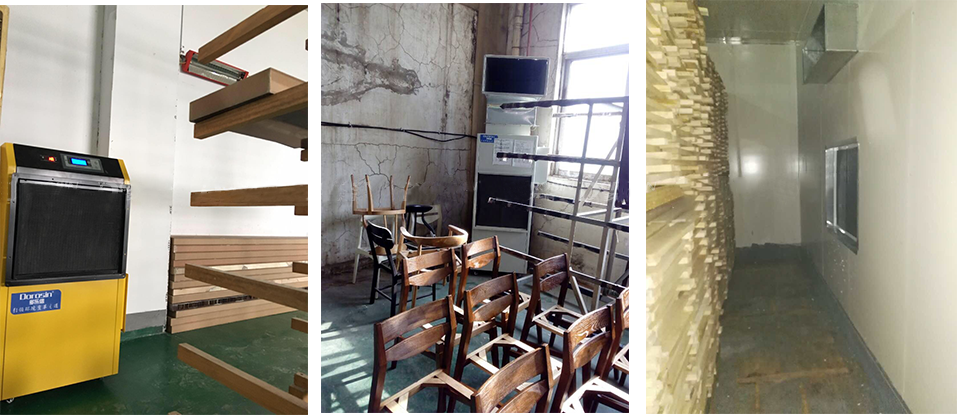

The drying dehumidifier is one of the most important parts of controlling wood moisture.Selecting the right drying equipment, coupled with correct operation, can ensure the quality of wood drying, but also to a greater extent to reduce investment and drying costs.However, there are a wide variety of wood drying methods and equipment nowadays, which require companies must need to choose suitable one based on the wood characteristic, request, and the scale of the enterprise and condition.

According to Dorosin research to more multiple furniture factories and interview investigation, there are problems on drying the wood, bad problems. Many furniture factories still use the traditional way "Oven", Heating the room by electricity or coal as fuel, and take advantage of external circulation of the fan to realize the drying treatment of wood. However, the convection circulation wind will take away a lot of heat in the drying room, and the fresh air will be reheated to the high temperature of 70-80℃, which not only prolongs the drying time, but also causes serious energy consumption. What's worse, the replacement of the old and new air makes the temperature of the drying room uneven, tend to generate crack on the wood, and the wood will be devalued or will need to be discarded! What a waste.

Of course there are other good wood drying methods, like steam drying, vacuum drying. The disadvantages are the high machine and operating cost which increase greatly the drying cost, not good for large-scale promotion and use. Dorosin wood drying dehumidifiers and HDHG- series high temperature resistant drying and dehumidifier, not only save a good amount of investest and operating cost, reduce the intensity of labor, but also greatly shortened the drying and processing cycle of wood. Make the drying quality of wood has been improved to a good level.