Electronics industry

Business background:

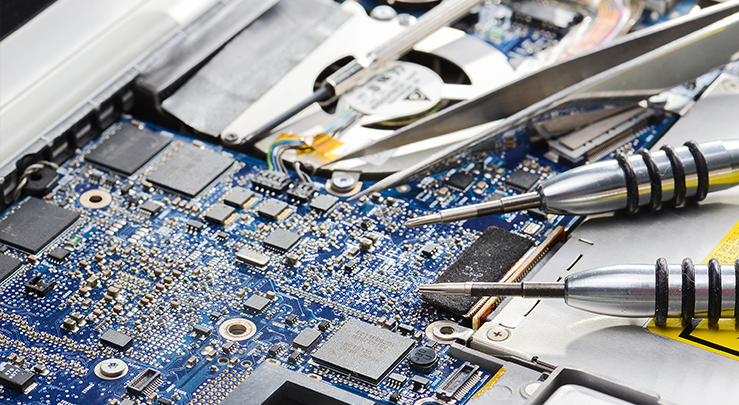

The electronics industry mainly develops and produces electronic equipment and various electronic components, devices, instruments, meters and other products, including SMT workshops, LCD factories, PSB factories, IC testing factories, packaging factories, semiconductor components factories, etc. The internal requirements of the production workshop are maintained stable environment, including the temperature and humidity in the workshop, the humidity in the electronic workshop is generally controlled within the range of 55 ± 5%.

In many cases, due to the weather, especially in typhoons or rainy seasons, the electronic workshop cannot always maintain a stable humidity environment. Once the humidity exceeds 60%, it will affect the quality of electronic products and easily cause material aging and leakage. And it will also affects the working performance of electronic products, and even causes the products to be scrapped due to damp, affects the product qualification rate, and brings immeasurable losses to the factory.

In many cases, due to the weather, especially in typhoons or rainy seasons, the electronic workshop cannot always maintain a stable humidity environment. Once the humidity exceeds 60%, it will affect the quality of electronic products and easily cause material aging and leakage. And it will also affects the working performance of electronic products, and even causes the products to be scrapped due to damp, affects the product qualification rate, and brings immeasurable losses to the factory.

For example, for products like integrated circuits. If the humidity is too high, humid air will penetrate the IC plastic package from the pin gaps into the IC, resulting in IC moisture absorption. Cause water vapor during the heating process of the SMT process. The resulting pressure will cause the IC resin package to crack, and oxidize the internal metal of the IC device, which will cause moisture and malfunction. Therefore, it is very necessary to equip the electronic workshop with dehumidification equipment.

General electronic factories are mainly engaged in various electronic components and electronic products, which have higher requirements for the production and storage of electronic products. The production workshop must keep air clean, be tidy, and free of corrosive gases. The warehouse must be anti-static, dust and mold, and avoid direct sunlight. It must meet the "5S" requirements.

In response to the needs of the electronics industry, Dorosin's humidity control system processing solution can ensure that the humidity in the workshop can be controlled between 50% and 60%, reducing the loss caused by low humidity in the workshop. Preventing metal parts from being corroded and the mechanical strength of the parts being reduced, to ensure that the quality and performance of the product will not be affected by excessive humidity.